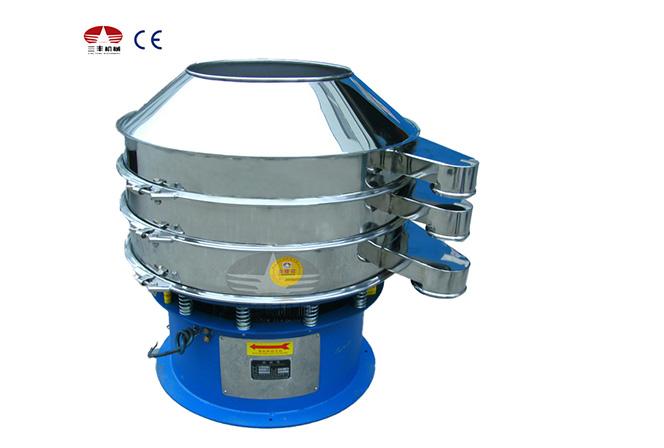

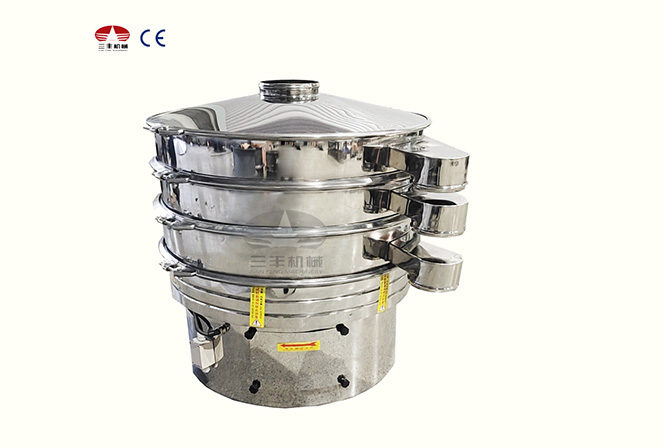

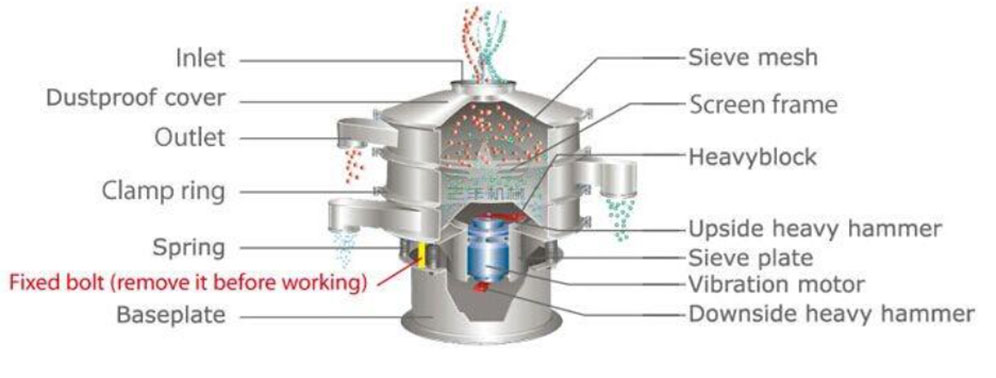

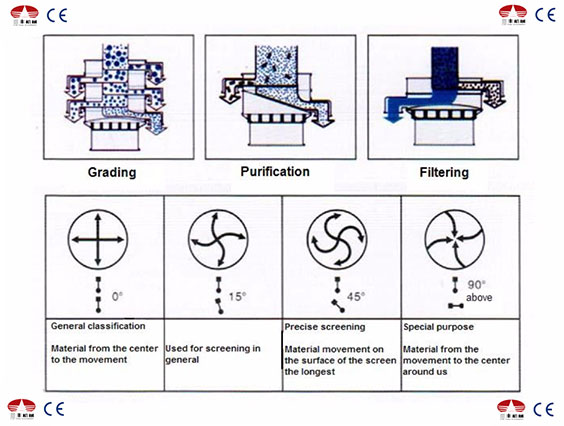

Standard Type Stainless Steel Vibrating Sieve are a traditional part of the classifying process of dry powders and filtering serous fluids. They sift materials by particle size through a screen. With high quality woven wire mesh screens and the ultrasonic screen technology, vibratory separators are now able to separate much finer materials .It adopts the principle of vibration to realize the sieving of plenty of raw materials ,which are highly suitable for the purposes of screening and sorting for grains, dry powders and filtering serous fluids in industries such as chemicals, food processing, pharmaceuticals, metallurgy, pigments, ceramics and abrasives among many other applications. SF vibrating sieve is suitable for continuous operation of automatic feed lines with high degree of mechanization, and the inflow port can be sealed. Sieve machine can be installed under four layers of screen, screening accuracy can reach 28µ, dust does not fly. The latest patented screen frame design has greatly improved screening efficiency, which fully meets the screening requirements of various industries.

|

Size |

SF-400 |

SF-600 |

SF-800 |

SF-1000 |

SF-1200 |

SF-1500 |

SF-1800 |

SF-2000 |

|

Efficient diameter screen (mm) |

390 |

540 |

730 |

900 |

1100 |

1400 |

1700 |

1886 |

|

Efficient screen area (m2) |

0.1207 |

0.2289 |

0.4183 |

0.6359 |

0.9499 |

1.5386 |

2.2687 |

2.7922 |

|

Layer(s) |

1-5 |

|||||||

|

Motor power for 1-3 layers (Kw) |

0.25 |

0.37 |

0.55 |

0.75 |

1.1 |

3 |

4 |

4 |

|

Motor power for 4-5 layers (KW) |

0.37 |

0.55 |

0.75 |

1.1 |

1.5 |

4 |

5 |

5 |

A circular vibrating screen machine consists of a screen box, a screen mesh, a vibration source, a base frame, and supporting springs. The eccentric vibration exciter is mounted on the side plate of the screen box and rotated by the motor through the V-belt. The rotation of the exciter generates an eccentric force, which causes the screen box to vibrate in a circular motion. As the material falls onto the screen mesh, the vibration from the screen box passes through the mesh and onto the supporting springs. The springs support the screen mesh, preventing it from sagging and ensuring efficient screening. The material that is smaller than the mesh opening gets through the screen, while larger pieces of material are moved to the edge of the screen and discharged through the discharge port. The working principle of the circular vibrating screen machine is based on the screening of materials, with the aim of separating them based on size, shape, and other properties.

Linear vibration screen is the use of vibration motor vibration principle, so that the material on the screen surface to throw a jump forward for linear movement, in order to reasonably match the screen to achieve the purpose of screening.

The linear tumbler screen machine is a versatile piece of equipment used for separating materials of different sizes and shapes by applying vibration to the screen surface. It is widely used in industries like food, pharmaceuticals, and chemicals for material classification, sorting, and sieving. Its high efficiency, large capacity, and low noise make it a preferred choice for industrial screening processes.

The high-frequency vibrating screen adopts a high-frequency two-stage motor with a rotating speed of 3000 times / min, which destroys the surface tension of the material and the high-speed vibration of the fine material on the screen surface.

Direct-discharge screen is a new type of screening equipment. Double vibration source can produce vortex motion on the screen surface. It adopts fully enclosed structure design, so it can effectively prevent the dust from spilling. At the same time, it is easy to install and adjust the assembly line.

The dewatering screen machine is an effective solution for removing moisture from a variety of materials. The machine applies a high centrifugal force to the material, separating the liquid from the solids and draining it through the screen. The process is efficient and reduces the need for separate drying equipment, making the dewatering screen machine a popular choice in industries such as mining, construction, and wastewater treatment.

Our company learns from foreign advanced technology and many years of production experience, combined with the circular structure and multi-layer scheme of swing-type rotor sieve, designed this light volume, small noise, space-saving, easy to move SF swing sieve. SF swing sieve unique mesh frame design, so that the screen for a long time and change the net fast.

Phone

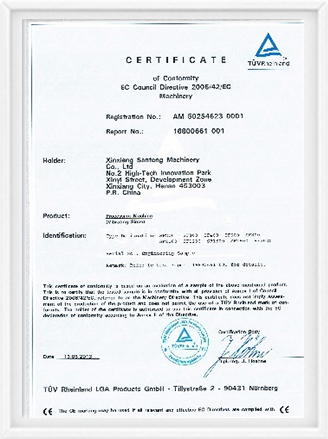

+86 13949618816Xinxiang Sanfeng Machinery Co., Ltd was founded in 2006. The company is advanced manufacturer of vibrating sieve,

Copyright © 2023 Xinxiang Sanfeng Machinery Co., Ltd.Power by yisainuo