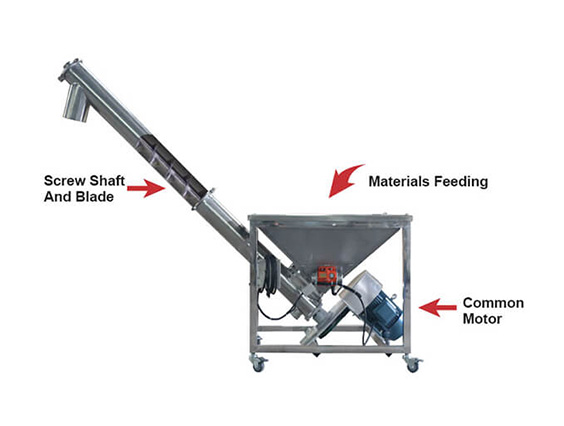

Tubular screw conveyor is a kind of conveying equipment with a wide range of uses. From the perspective of conveying material displacement direction, screw conveyor is divided into horizontal type, inclined type and vertical type, which is mainly used for conveying and lifting all kinds of loose materials such as powder, granular and small pieces. Screw conveyor is a kind of machinery that uses motor to drive screw rotation and push materials to achieve the purpose of conveying.

– Used to move materials horizontally or at an angle

– Can handle various types of materials, such as powders, granules, and even semi-solid materials

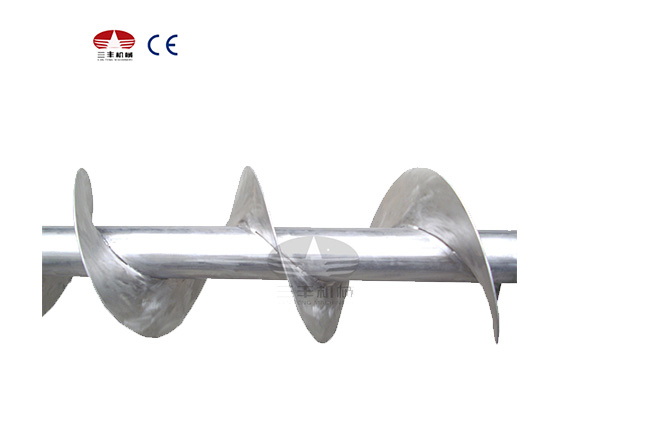

– Consists of a screw or auger, which rotates in a cylinder or trough to move the materials forward

– Can be customized with different materials, coatings, and configurations to suit specific applications

| Type | Spiraldiameter (mm) |

Screwpitch (mm) |

Speed (r/min) |

Transport capacity (m³/h) |

Speed (r/min) |

Transport capacity (m³/h) |

Speed (r/min) |

Transport capacity (m/h) |

Speed (r/min) |

Transport capacity |

|

| D | S | N | w=0.33 | N | =0.33 | N | u=0.33 | N | w=0.33 | ||

| Smal-scale | LS100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| LS125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| LS160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| LS200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium scale |

LS250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 7.8 | 45 | 10.9 |

| LS315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| LS400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large-scale | LS500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| LS630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| LS800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Super sized |

LS1000 | 1000 | 560 | 32 | 277.9 | 25 | 217.1 | 20 | 173.7 | 16 | 139 |

| LS1250 | 1250 | 630 | 25 | 381.7 | 20 | 305.4 | 16 | 244.3 | 13 | 198.5 | |

The screw conveyor is a mechanical conveying system that moves bulk materials such as granules, powders, and flakes. The system uses a rotating screw blade that consists of a helical flighting that moves the material along a trough. The screw rotates within a fixed casing, and as it rotates, it carries the material forward through the trough. The speed of the screw can be adjusted to control the rate of material delivery. The screw conveyor is a simple and effective solution for many industries, and its versatility makes it ideal for use in a wide range of applications.

A chain conveyor is a mechanical system that uses a continuous chain to transport materials or goods along a fixed path. In a chain conveyor, the chain is connected to sprockets or wheels, which control the movement of goods. These conveyors can be used for a variety of materials, including heavy goods, bulk materials, and sharp-edged objects. Chain conveyors are used in several industries like automotive, bottling, food processing, manufacturing, and packaging.

A bucket elevator is a mechanical conveying system that allows materials to be vertically transported with ease. Originally designed for the agriculture industry in the 19th century, bucket elevators have since become an essential component in many manufacturing and processing facilities.

Ultrasonic vibrating screen is composed of vibrating screen and ultrasonic wave source. It converts 220V, 50Hz or 110V, 60Hz electric energy into 36kHz high-frequency electric energy, inputs ultrasonic transducer and turns it into 36kHz mechanical vibration. The generated power ultrasonic makes the screen vibrate at high frequency.

The standard test screen (200 mm) is a standard test screen which can be installed with a standard test screen frame with a diameter of 200 mm. The standard inspection screen frame with diameter of 200mm is a common screen frame in laboratory.

Standard Type Stainless Steel Vibrating Sieve are a traditional part of the classifying process of dry powders and filtering serous fluids. They sift materials by particle size through a screen. With high quality woven wire mesh screens and the ultrasonic screen technology, vibratory separators are now able to separate much finer materials .

Linear vibration screen is the use of vibration motor vibration principle, so that the material on the screen surface to throw a jump forward for linear movement, in order to reasonably match the screen to achieve the purpose of screening.

Phone

+86 13949618816Xinxiang Sanfeng Machinery Co., Ltd was founded in 2006. The company is advanced manufacturer of vibrating sieve,

Copyright © 2023 Xinxiang Sanfeng Machinery Co., Ltd.Power by yisainuo