The high-frequency vibrating screen adopts a high-frequency two-stage motor with a rotating speed of 3000 times / min, which destroys the surface tension of the material and the high-speed vibration of the fine material on the screen surface. On the other hand, it increases the probability of the material smaller than the separation particle size contacting the screen hole, so as to improve the screening filtration, which is suitable for the filtration of fine-grained and high concentrated slurry materials.

1. Small size, light weight, easy to move, the height of the vibrating screen can be adjusted by itself, the coarse material and the standard material after passing through the screen can be automatically discharged at each outlet, which can be operated automatically.

2. Fine screening precision, perfect function, any powder, particle, mucus can be applied 3. Mesh does not block, powder does not fly, screening mesh up to 400 mesh.

| Type | Screen diameter(mm) | Motor power(KW) | Speed(r/min) | Centrifugal force(KN) |

| SF-G450 | Φ430 | 0.12 | 2800-3000 | 2 |

| SF-G600 | Φ580 | 0.18 | 2800-3000 | 3 |

| SF-G800 | Φ760 | 0.37 | 2800-3000 | 5 |

| SF-G1000 | Φ910 | 0.55 | 2800-3000 | 8 |

| SF-G1200 | Φ1120 | 0.75 | 2800-3000 | 11 |

A high-frequency vibrating screen operates on the principle of controlled vibration. This machine uses a high-frequency vibration that causes the screen mesh to accelerate through the material to be sifted, separating the particles based on their size. The screen mesh is mounted at an angle that enables gravity to assist in the separation process, as the smaller particles fall through the screen openings onto the smaller lower deck and are discharged. The larger particles move along the screen surface, moving towards the discharge outlet where they are collected. The high-frequency vibrating screen can effectively separate material ranging from solid particles to liquids. The sieving process is continuous and efficient, and the machine requires minimal maintenance, making it a cost-effective solution.

The airflow screen machine is a versatile screening tool that uses a combination of forced air and vibratory motion to sift and separate materials of varying sizes. These machines are designed to handle a range of materials, including powders, granules, and pellets, and are particularly effective for separating fine particles.

Our company learns from foreign advanced technology and many years of production experience, combined with the circular structure and multi-layer scheme of swing-type rotor sieve, designed this light volume, small noise, space-saving, easy to move SF swing sieve. SF swing sieve unique mesh frame design, so that the screen for a long time and change the net fast.

The dewatering screen machine is an effective solution for removing moisture from a variety of materials. The machine applies a high centrifugal force to the material, separating the liquid from the solids and draining it through the screen. The process is efficient and reduces the need for separate drying equipment, making the dewatering screen machine a popular choice in industries such as mining, construction, and wastewater treatment.

Direct-discharge screen is a new type of screening equipment. Double vibration source can produce vortex motion on the screen surface. It adopts fully enclosed structure design, so it can effectively prevent the dust from spilling. At the same time, it is easy to install and adjust the assembly line.

The linear tumbler screen machine is a versatile piece of equipment used for separating materials of different sizes and shapes by applying vibration to the screen surface. It is widely used in industries like food, pharmaceuticals, and chemicals for material classification, sorting, and sieving. Its high efficiency, large capacity, and low noise make it a preferred choice for industrial screening processes.

Linear vibration screen is the use of vibration motor vibration principle, so that the material on the screen surface to throw a jump forward for linear movement, in order to reasonably match the screen to achieve the purpose of screening.

Standard Type Stainless Steel Vibrating Sieve are a traditional part of the classifying process of dry powders and filtering serous fluids. They sift materials by particle size through a screen. With high quality woven wire mesh screens and the ultrasonic screen technology, vibratory separators are now able to separate much finer materials .

Phone

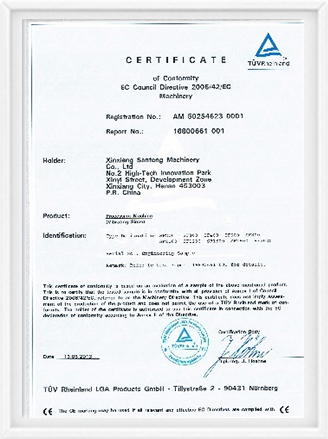

+86 13949618816Xinxiang Sanfeng Machinery Co., Ltd was founded in 2006. The company is advanced manufacturer of vibrating sieve,

Copyright © 2023 Xinxiang Sanfeng Machinery Co., Ltd.Power by yisainuo