Our company learns from foreign advanced technology and many years of production experience, combined with the circular structure and multi-layer scheme of swing-type rotor sieve, designed this light volume, small noise, space-saving, easy to move SF swing sieve. SF swing sieve unique mesh frame design, so that the screen for a long time and change the net fast. Up to 5 times the output per unit area, accurate to multistage separation, high screening efficiency, design precision and durability, any powder, irregular shape particles can be screened. The mesh holes are not blocked, the powder is not flying, and can be screened to 500 mesh or 0.028mm. Impurities and coarse materials are automatically discharged and can be worked continuously.

1. Up to 5 times of unit area output, screening efficiency up to 90-95%

2. The screen holes will not be blocked and the dust will be removed airtight

3. The acceleration is 4.5 times lower than that of the vibrating screen, the life of the screening parts is increased and the maintenance is reduced

4. Optimized rebalancing and low dynamic load on the foundation

| Size | SF-YBS 1000 | SF-YBS 1200 | SF-YBS 1600 | SF-YBS 2000 | SF-YBS 2600 |

| Diameter screen(mm) | 1040 | 1250 | 1580 | 1880 | 2650 |

| Efficient Diametereen(mm) | 900 | 1100 | 1340 | 1340 | 1940 |

| Efficient screen area(m²) | 0.71 | 1.11 | 1.83 | 2.62 | 5.31 |

| Layer(s) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Motor power(KW)(1-3 layers /4-5 layers) | 1.5/1.5 | 2.2/2.2 | 2.2/4 | 2.2/4 | 5.5/5.5 |

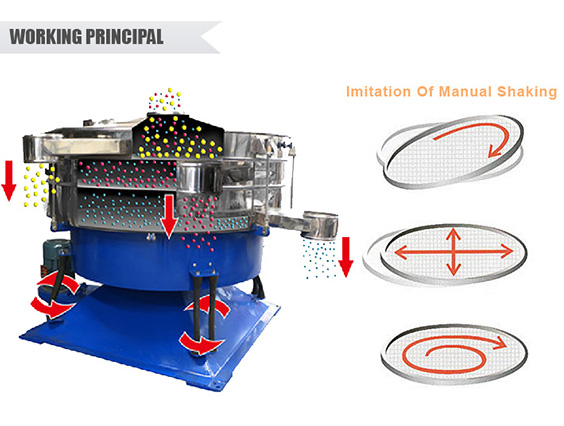

Circular tumbler screen machine works by rotating an inclined circular screen on a vertical axis. Material is fed onto the center of the screen and as the machine rotates, the material is lifted and thrown by the screen's radial force. The screen's multi-plane inertial vibration causes the material to move across the screen and be sorted into its different sizes or fractions.

The airflow screen machine is a versatile screening tool that uses a combination of forced air and vibratory motion to sift and separate materials of varying sizes. These machines are designed to handle a range of materials, including powders, granules, and pellets, and are particularly effective for separating fine particles.

The dewatering screen machine is an effective solution for removing moisture from a variety of materials. The machine applies a high centrifugal force to the material, separating the liquid from the solids and draining it through the screen. The process is efficient and reduces the need for separate drying equipment, making the dewatering screen machine a popular choice in industries such as mining, construction, and wastewater treatment.

Direct-discharge screen is a new type of screening equipment. Double vibration source can produce vortex motion on the screen surface. It adopts fully enclosed structure design, so it can effectively prevent the dust from spilling. At the same time, it is easy to install and adjust the assembly line.

The high-frequency vibrating screen adopts a high-frequency two-stage motor with a rotating speed of 3000 times / min, which destroys the surface tension of the material and the high-speed vibration of the fine material on the screen surface.

The linear tumbler screen machine is a versatile piece of equipment used for separating materials of different sizes and shapes by applying vibration to the screen surface. It is widely used in industries like food, pharmaceuticals, and chemicals for material classification, sorting, and sieving. Its high efficiency, large capacity, and low noise make it a preferred choice for industrial screening processes.

Phone

+86 13949618816Xinxiang Sanfeng Machinery Co., Ltd was founded in 2006. The company is advanced manufacturer of vibrating sieve,

Copyright © 2023 Xinxiang Sanfeng Machinery Co., Ltd.Power by yisainuo